UpKeep AI Suggestion

Search Results

Blog Post

How to Create a Preventive Maintenance Checklist

Preventive maintenance checklists protect your team, your customers, and your bottom line. Learn how to create one with UpKeep, making big projects easy to tackle.

Published on March 21, 2024

Loading...

Want to keep reading?

Good choice. We have more articles about maintenance!

Article

7 Tips For a Better Preventative Maintenance Program

This concise guide shows you how to prioritize assets for a preventive maintenance program and how to activate that program.

Article

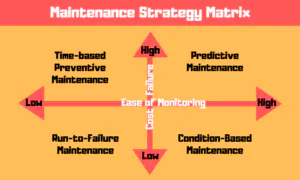

A Step By Step Guide to Choosing the Right Maintenance Strategy for Your Equipment

Choosing the right maintenance strategy for a given asset requires you to assess the cost of failure and the ease...

Article

Examples of Preventive Maintenance That Save and Waste Money

Preventive maintenance cost does not always save your organization money. In this post, we look at examples of when it...

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)